Release time:2023-10-17

As we all know, temperature is a very important factor in the whole process of the injection molding factory, and its level will immediately endanger the quality of the parts of the injection molding factory. Therefore, each injection molding factory company has a set of extremely reasonable management regulations for the temperature of the injection molding factory. So, what are the disadvantages of high temperature in the injection molding plant? How should we deal with the problem of high temperature?

1. Thermal deformation of mechanical equipment: the fitness components with different thermal expansion indexes in the hydraulic components are stuck due to mutual cooperation and exercise contraction, resulting in poor posture, endangering the accuracy of the transmission system of the hydraulic transmission system and reducing the working quality of the components.

2. Reduce the viscosity of the oil: if the temperature of the plastic machine is too high, the viscosity of the oil will be reduced, the leakage will increase, and the capacity efficiency of the pump and the efficiency of all system software will be significantly reduced. As the viscosity of the oil decreases, the floating oil of moving parts such as rotary vane pump becomes soft and cut, and the friction increases, resulting in increased damage.

3. Deformation of rubber products: if the temperature of the plastic machine is too high, the rubber products will deform, accelerate the embrittlement and failure, reduce the sealing characteristics and service life, and cause leakage.

4. Accelerate the air oxidation and mildew of hydraulic oil: if the temperature of the plastic machine is too high, it will accelerate the air oxidation and mildew of hydraulic oil, dissolve and lose chemicals, and reduce the service life of gear oil. Dissolved substances block the damping small round hole and clearance valve, causing the pressure valve to be stuck and unable to stand, and the metal hose to stretch and bend, or even crack.

5. Reduce the working quality of components: due to the high temperature rise of the plastic machine, the working quality of components is reduced, and the dissolved gas in the oil escapes, causing cavitation, resulting in the reduction of the working characteristics of the hydraulic transmission system.

6. The cooling tower has serious scaling, which blocks the cooling circulating water channel and adheres to the wall of the water channel, resulting in poor actual cooling effect, high water temperature and endangering production and manufacturing. There is no incoming material under the colloidal solution. The more serious problem is that the software of the sealing system of the rubber injection hydraulic cylinder is poor, and the sealing ring is heated and deformed, resulting in oil leakage.

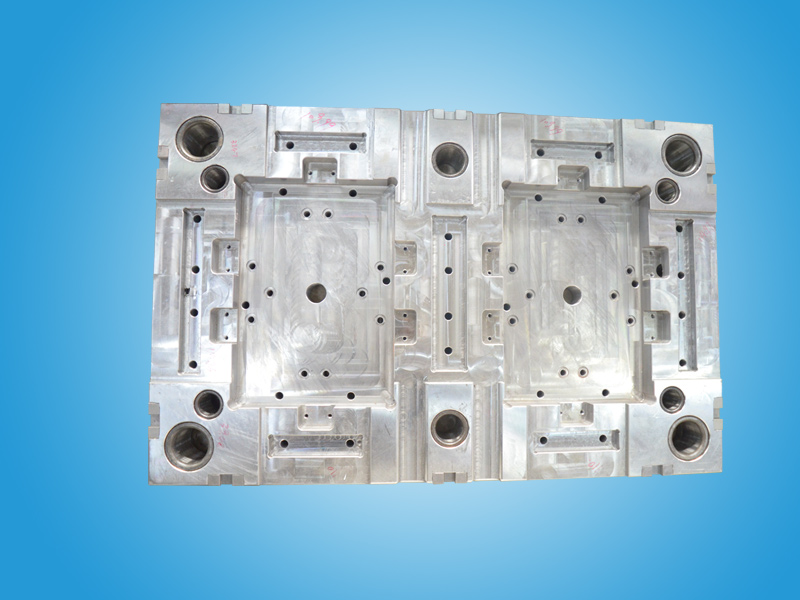

7. The dirt in the water channel and water dividing block of the abrasive tool will cause the actual cooling effect of the abrasive tool to be very poor, resulting in the increase of defective products, the decrease of productivity and the difficulty of removal.